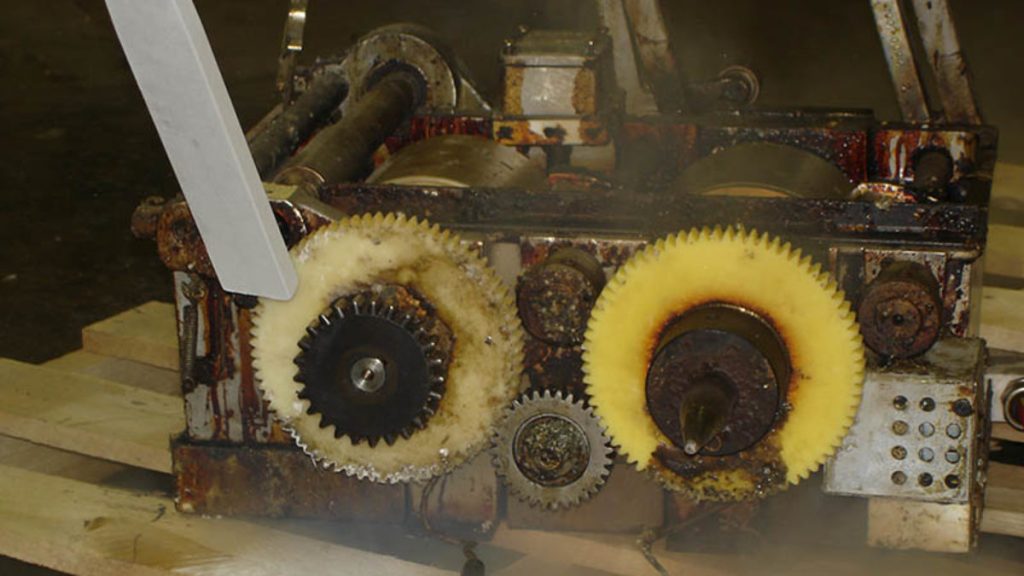

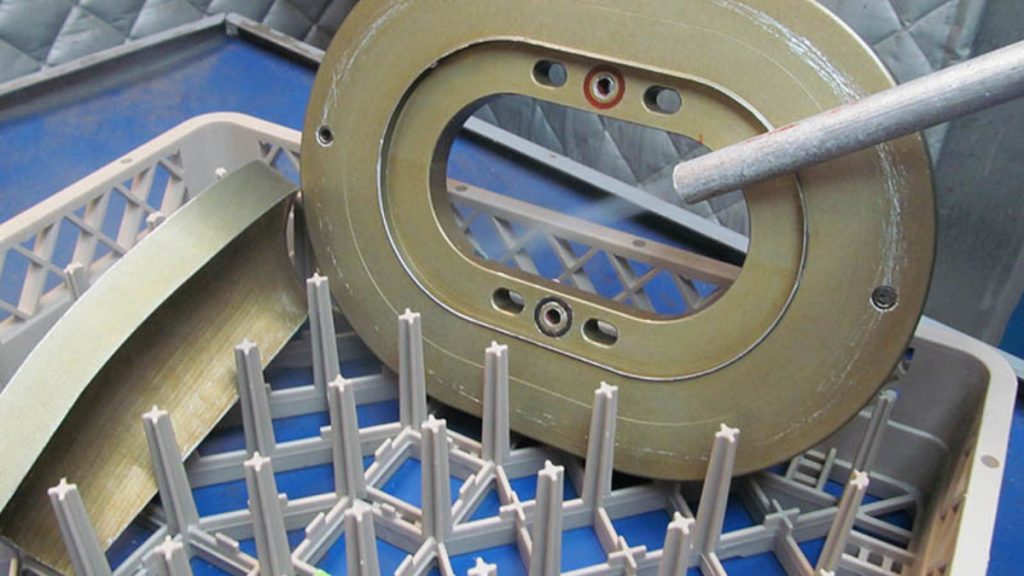

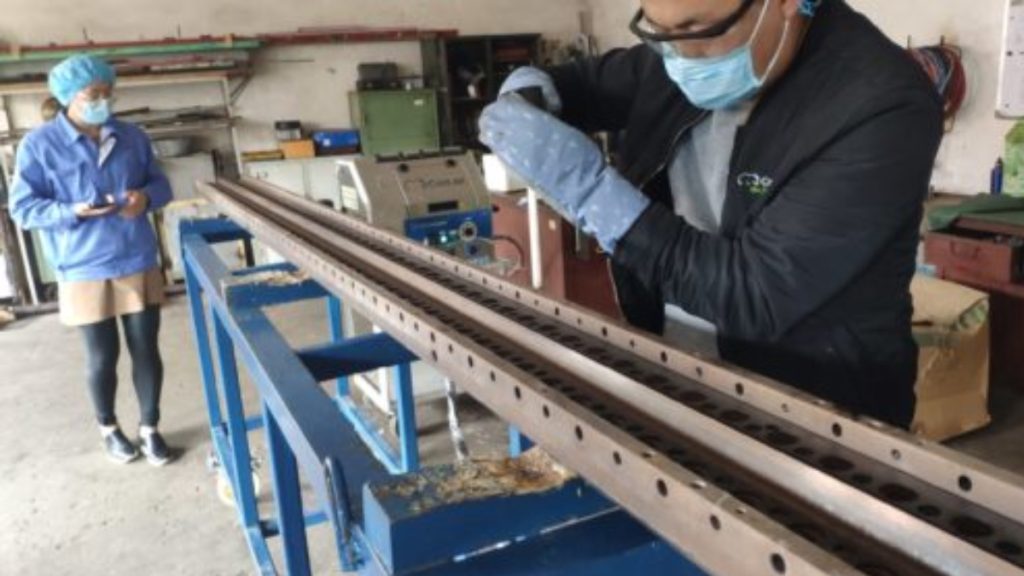

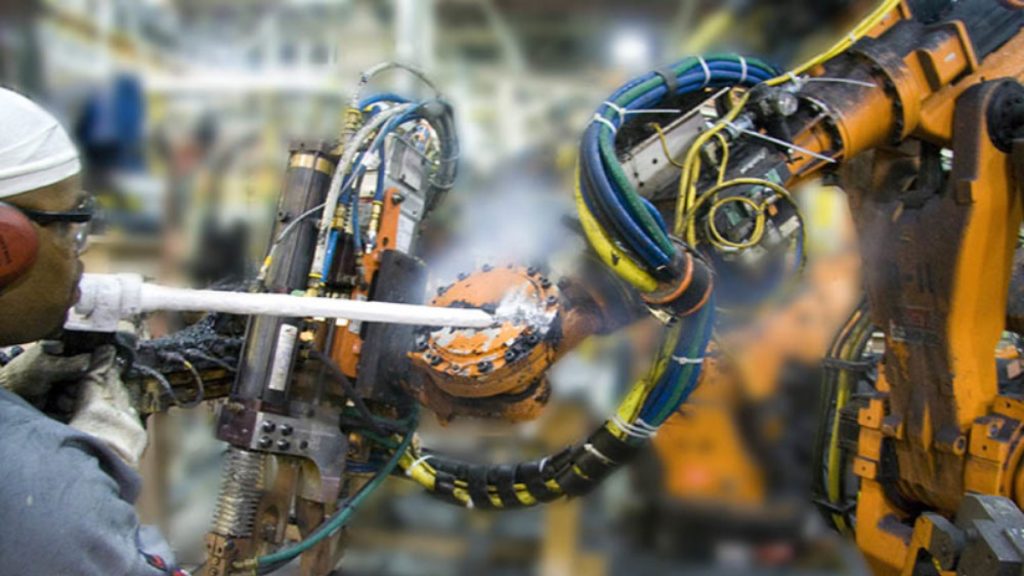

Dry Ice blasting is a revolutionary blasting method in which dry ice pellets replace traditional blasting materials like sand, water, walnut, glass, plastic, etc. In contrast to sand blasting etc. the process leaves no secondary waste material. The process is dry and non-conductive, and it is therefore suitable for use on electrical motors and electrical circuits.

“It is a non-toxic, Non-abrasive cleaning method where no waste materials are produced”